Best Press Brake Manufacturer in 2026

It is not your competition that poses the greatest threat to the profitability of your shop, it is the weeks in the queue when you are awaiting a metal supplier. The way to regain that control, and to reclaim that margin, is to bring bending in-house, using a machine known as a press brake.

It can be said to be a large, computer-controlled karate chop on sheet metal. The task of a press brake is to produce clean and precise bends, and convert a sheet of metal or aluminum into a useful 3D object.

It is made with two tools of press braze, one on top, a punch, and a die on the bottom. It is the way a piece of the paper turns into a metal shelf. Such fundamental procedure is central to the awareness of what to consider when purchasing a press brake to attain consistency in the accuracy of bending sheet metal.

Hydraulic vs. Electric: Choosing Your Press Brake's 'Engine'

After deciding that you require a press brake, the most basic decision you do is the power. It is the hydraulic press brake versus the electric press brake slugfest and it comes down to the matter of a choice between brute strength and finesse precision. Masculinity versus femininity Imagine a bulldozer as the alternative to high-performance electric car- both of these beasts can be powerful, but they are effective at different things.

For decades, hydraulic machines were the standard. They operate using fluid pressure, making them incredibly strong and reliable.

- Hydraulic (The Workhorse)

- Pro: Immense power for bending very thick, tough materials.

- Pro: Generally has a lower initial purchase price.

- Con: Slower and uses more energy, as the motor often runs continuously.

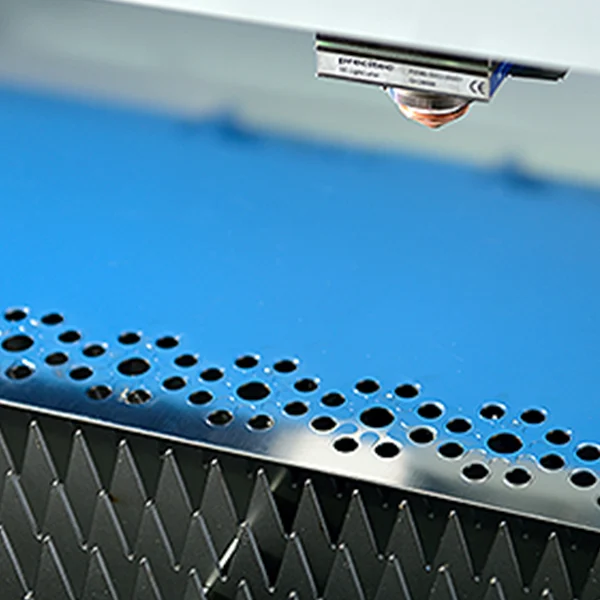

Electric press brakes are the modern alternative, prized for their speed and efficiency. They use powerful electric motors that only draw significant power during the bend itself. This is key for improving sheet metal bending accuracy and lowering your electricity bill.

- Electric (The Precision Athlete)

- Pro: Extremely fast, quiet, and energy-efficient.

- Pro: Very precise and repeatable, perfect for complex or high-volume parts.

- Con: A higher upfront cost is typical for this newer technology.

If your work involves thick materials and your budget is tight, a hydraulic machine is a solid starting point. But if you’re running a high-production shop where speed, accuracy, and long-term energy costs are paramount, an electric brake is likely the smarter investment.

How Much 'Strength' Do You Need? A Simple Guide to Press Brake Tonnage

Once you choose the engine of your machine, the other major consideration is its power which is referred to as tonnage. The maximum pressing force of the machine is tonnage. A heavy sheet of cardboard takes greater strength to fold than a sheet of thin paper; and that strength is tonnage measured in tons. It is one of the fundamental elements of any press brake purchasing guide that is not advanced.

The quantity of tonnage you will need will depend on the thickness of the metal and on the length of the bend. A 10-foot long bend on a heavy steel plate needs much more effort than a short bend on a small aluminium bracket. Finding the correct power of the machine to the amount of parts that you want to fabricate is a critical process that anyone attempting to determine how to select a press brake in a little shop should consider.

You do not need to speculate, thank God. All the manufacturers offer explicit tonage diagrams that will do the hefty labor on your behalf. Knowing what you are dealing with and which parts you will be developing will allow you to easily identify the correct level of power that you require and then you can purchase a sufficient amount of machine without wasting money.

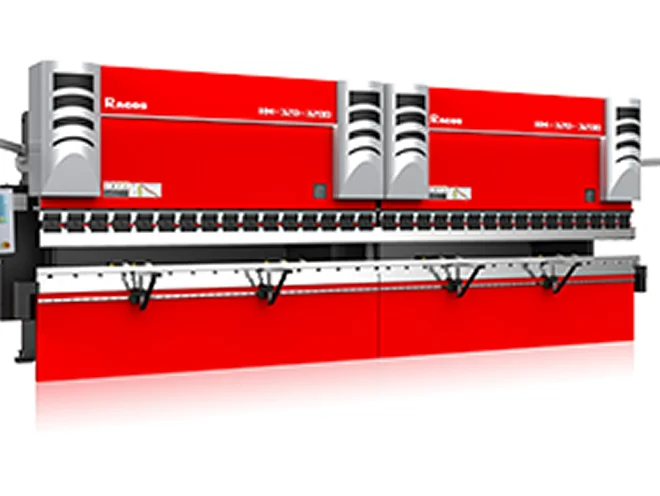

Who Are the Top Press Brake Brands? A Map of the Market

After you have the type and tonnage you want, it is a good idea to put the market into two or three key categories so as to identify the best manufacturer of a press brake to meet your needs. Comparison of the top press brakes brands is not concerning which one is better or worse, but which one is the best solution regarding your budget as well as objectives. There are the brands that extend the boundaries of technology and those that concentrate on rock-solid machines that do provide impressive value.

To simplify your search, here’s how the market generally breaks down:

- The Industry Giants (TRUMPF, Amada): These are the leading industrial press brake companies, known for cutting-edge technology and bulletproof reliability. They are the premium choice for high-volume, high-precision manufacturing.

- The High-Value Contenders (Accurpress, Baileigh): These brands are famous for building robust, dependable machines at a more accessible price point. They are often a fantastic starting point for small shops or businesses bringing fabrication in-house.

Choosing a brand is a great start, but the physical machine is only half the story. The machine's software and the quality of customer support can be just as important as the steel it’s made from.

Why the Best Machine Isn't Just Metal: Software and Support Matter

A powerful machine is useless if you can’t easily tell it what to do. The controller is its brain—some CNC press brake controller options are intuitive like a smartphone, while others are frustratingly complex. A user-friendly interface is the difference between making parts smoothly and wasting hours on setup.

Just as important is what happens when a part eventually breaks. Strong press brake manufacturer support and service is like having a great mechanic down the street instead of in another state. When your machine stops, every hour of downtime costs you real money, so fast, local support is a massive financial advantage.

Before you make a final decision, always ask a representative, "Where is your nearest service technician based?" This question is a critical part of any new or used press brake inspection checklist. Their answer reveals their commitment to keeping you operational.

Your Next Steps: How to Get a Smart Quote for Your First Press Brake

Such words as tonnage or backgauge could have been unknown just a little while ago. At this point, you can be sure to talk about the types of machines and what to look at making the purchase that may have considered as complicated into one that is easy to understand.

The act of asking the question, How much does a new press brake cost? is not the first step towards doing anything useful. It will be planning your project information and essential questions. This is a practical approach to any manufacturer as it makes you look like you are a serious partner, not a mere window shopper, and therefore will make your response be more accurate.

A perfect partner is a necessity as a machine. Good support, good service and a machine which does what it claims to do is what will really make your business strong to be able to contribute towards your business in the coming years.